Features of Angle Seat Valve

- With valve open or closed position display

- Pneumatic external pilot, can increase the service life, maintenance-free

- There is a self-adjusting seal gland between the overflow port and the slider to improve the sealing performance

- Y-type structure design enabling large flow (compared with globe valve), compact structure, fast response

Technical Specification

- Medium Temperture : -10℃~+180℃

- Ambient Temperture : -10℃~+60℃

- Max. Working Pressure : 1.6MPa

- Working Medium : Netral and aggressive liquid, gases

- Working Pressure : 0.4~0.8MPa

- Orifice Size : DN15-DN100

- Body Material : SS304 , SS316

- Actuator Material : Polyamide

- Sealing Material : PTFE

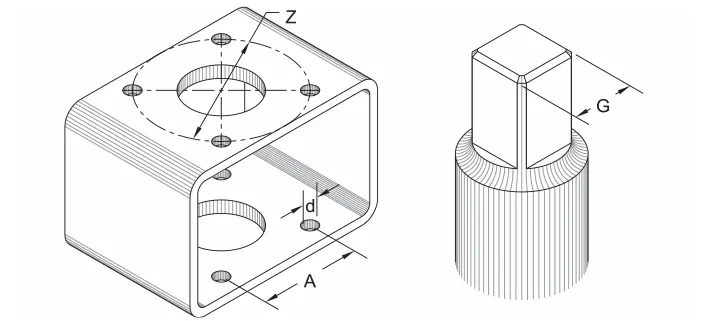

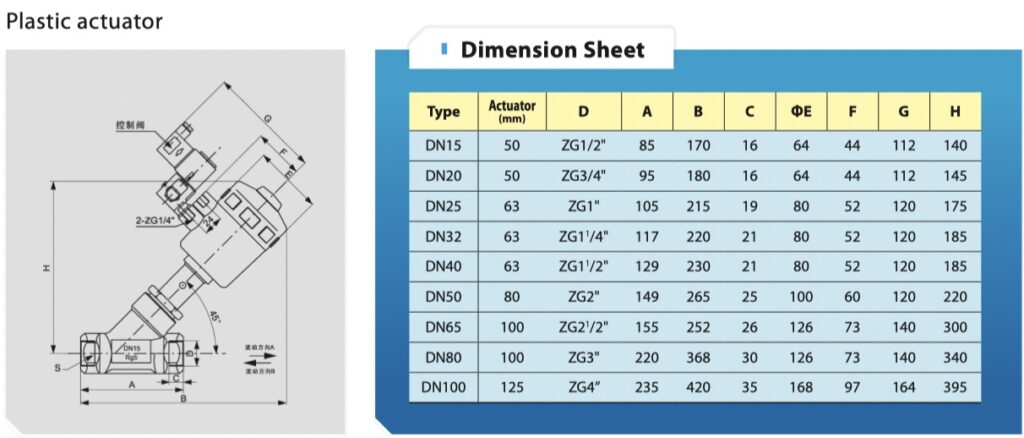

Dimension

Flow direction

Flow direction below the seat (direction A)

1.Valves with flow direction below the seat (direction A) ensure long service life

2.Valves used for liquid media are waterhammer-free

3.Valves with orifice DN15/DN20/DN25 are ideal for the operating pressure of 0.3Mpa

Vavles with orifice DN32/DN40 are operated with double-acting actuators DN100

Valves with orifice DN50 are operated with double-acting actuators DN125

สารบัญเนื้อหา

ToggleFlow direction above the seat (direction B)

Valves with dirction B provide high sealing integrity, used for steam and gases media.

There is a danger of waterhammer ,when the valves used for liquid media.

Installation & Maintenance

1. Clean the pipes carefully from any residue, dribble or welding residue, to avoid any damage to the seal. 2. To be installed as required, preferably with actuator in upright position

3. Connect the pipes according to the reference points (flow direction) found on the valve body.Only disassemble the actuator if required by customer

4. Before taking the valve apart, depressurize the media supply and pilot air supply piping system